Typical rigging floor markings

In an effort to reduce confusion and in order to provide a safer work environment the standard for down rigging has been adopted.

This guide is also available for download in Printer-friendly PDF format.

Note: Working shackle placement and bowline size.

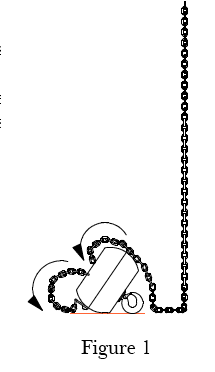

When floating a motor it is a good idea to lay the motor on

its side so that the dead end of the chain is on the lower side next to

the floor. The chain on the opposite side, that is being run into the

motor, should be stretched out away from the motor so that it feeds in

a straight line across the floor towards the motor.

( Figure 1)

Always watch the chain running into the motor and do not allow slack or twisted links, that may become lodged, to enter the motor. When running motor out, DO NOT run the chain out to the limit and leave it, always leave at least two and a half to three of chain on the dead end side. This will prevent the limit switch from cycling due to vibration from shipping. It will also allow time to check that the motor is running in the proper phase direction.

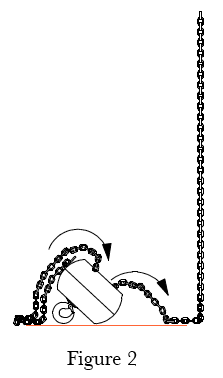

When running chain motor out it is helpful to lay the motor on

its side so that the dead end of the chain side is on the up side with

chain outstretched.

( Figure 2)

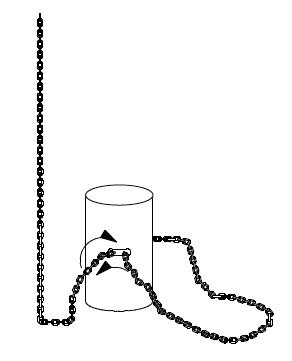

Warning! Never operate or store motor's in this position;

Motor may tip over and break casing. Lubricant could also leak

onto the brake system causing slippage